Bulk loading positioners

In the many years that we have been the specialist when it comes to bulk loading we have engineered, produced and assembled several custom made positioner systems. Our positioners have been used in projects such as PTA plants, flower mill plants, sugar plants and cement plants.

Some information about the Veenstra Positioners;

- Loading capacities of dry material depending on the product of up to 1000 m³/h

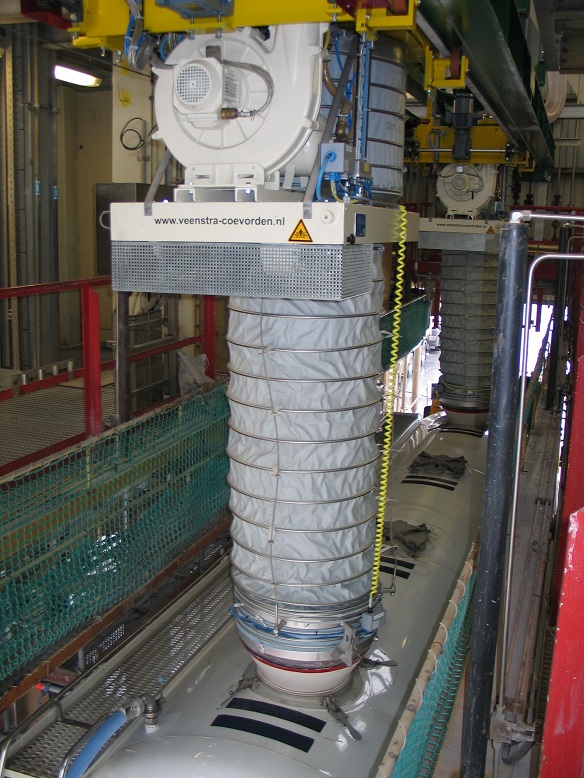

- Loading Spout bellow is a double wall construction with stainless steel inner cups.

- Systems can include dust extraction, a rubberised cone and level control.

- Veenstra positioners have been running reliable for many years

- Engineered to client specifications

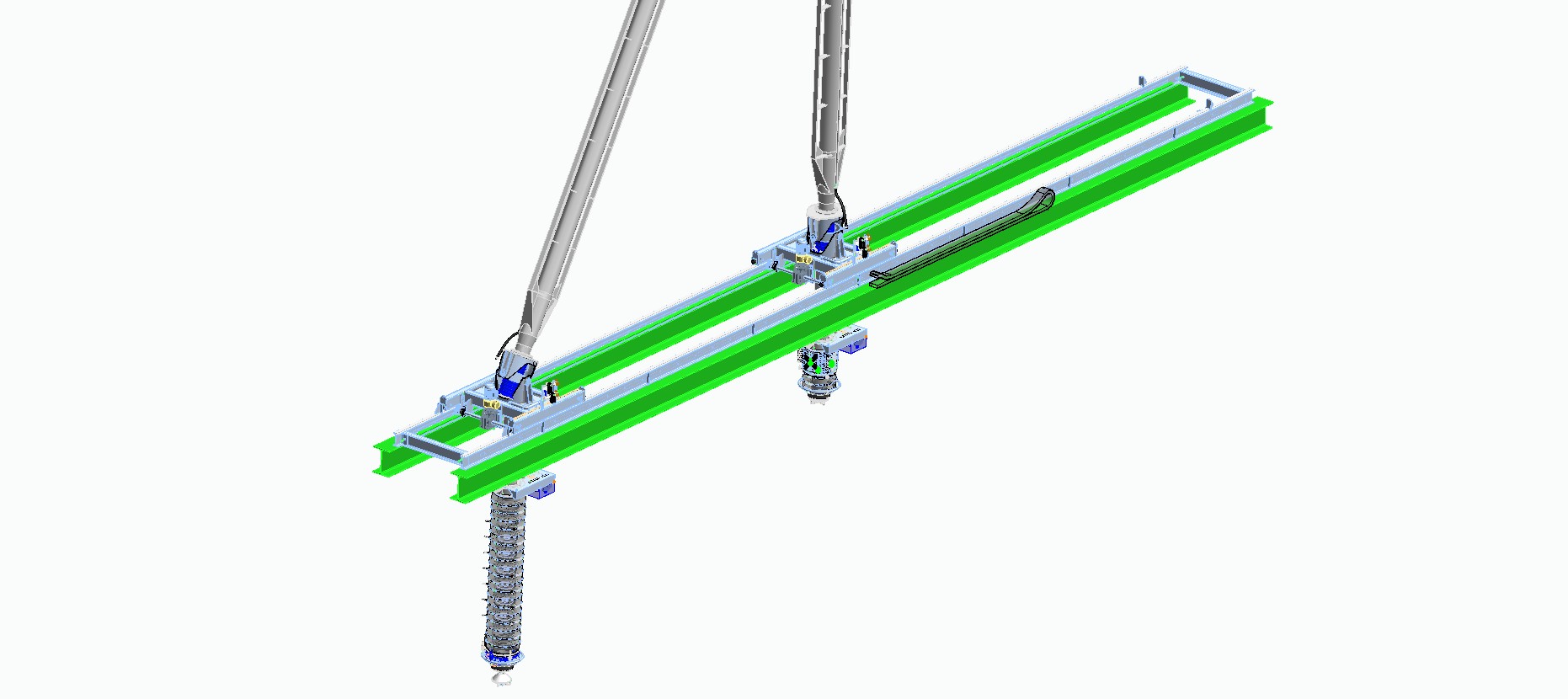

Single or double axle movement

The Veenstra Positioner systems are the ideal units for loading Trucks and Trains. Veenstra positioners can be designed with single or double axle movement of the loading spout. Controllable by joy stick the loading spout can be moved to each filling hatch without the need to move the truck to a different position. With an integrated filter system the truck can be filled quickly and dust free. The whole system can be controlled by one operator.

All Veenstra bulk loading systems are engineered in-house and to client specifications. Furthermore our product are designed in such a way that you can easily combine Veenstra equipment to create the perfect bulk loading setup. Our specialist are available to review your current loading station (or to be build station) and provide expert advice on improvements that can greatly boost your loading capacity.